Ecology

Emissions and Energy

HHLA has reported on its carbon footprint regularly since 2008 as part of the international Carbon Disclosure Project (CDP). The CDP is a non-profit initiative that manages one of the world’s largest databases of corporate greenhouse gas emissions on behalf of institutional investors and makes this information available to the public.

HHLA calculates its CO2 emissions on the basis of the Greenhouse Gas Protocol Corporate Standard (revised edition), a global standard for recording greenhouse gas emissions. Within the HHLA Group, emissions mainly relate to CO2. These are primarily influenced by throughput and transport volumes, traction services provided by the Group’s own locomotives and the use of electricity from renewable sources. In line with the Greenhouse Gas Protocol, electricity procured separately from renewable sources was classified as carbon-neutral. The power needed by a terminal depends largely on the number of seaborne containers it handles and the number of containers transported over land by rail and truck. HHLA uses seaborne and onshore throughput as an effective indicator to determine specific CO2 emissions in line with the recommendations of the European Economics Environment Group (EEEG).

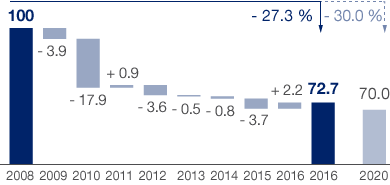

HHLA has set itself the target of reducing specific CO2 emissions – the CO2 emissions per container handled – by at least 30 % by 2020. The 2008 figures serve as the baseline here. In the period from 2008 to 2016, the company succeeded in reducing CO2 emissions by 27.3 % per container handled. Specific CO2 emissions increased by 2.2 percentage points in the year under review.

Reduction in Specific CO2 Emissions since 2008

Climate protection target: 30 % reduction by 2020

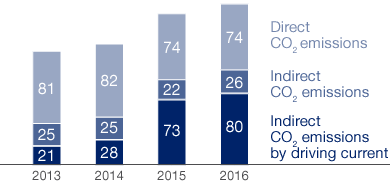

Direct and Indirect CO2 Emissions

in thousand tonnes

Absolute CO2 emissions rose by 5.5 % or 9,378 tonnes year-on-year to 178,468 tonnes. This is mainly attributable to the higher utilisation of the company’s own fleet of environmentally friendly electric multi-system locomotives. Traction-related emissions increased by 9.2 % or by 6,760 tonnes from 73,369 tonnes to 80,129 tonnes. Absolute emissions from all container terminals operated by HHLA rose by 4.6 % or 3,004 tonnes to 68,161 tonnes in the year under review.

HHLA conducted various CO2 reduction projects to decrease CO2 emissions at its companies in the reporting period. Examples include the optimization of energy-relevant system settings and the modernization of existing lighting systems. Further projects were set up and will start to bear fruit in 2017.

|

2013 |

2014 |

2015 |

2016 |

||||||||

|

||||||||||||

Diesel and heating oil in million litres |

26.8 |

28.5 |

25.7 |

25.6 |

||||||||

Petrol in million litres |

0.1 |

0.1 |

0.1 |

0.1 |

||||||||

Natural gas in million m3 |

3.1 |

1.8 |

2.3 |

2.4 |

||||||||

Electricity1 in million kWh |

148.7 |

154.4 |

138.3 |

139.6 |

||||||||

thereof from renewable energies |

78.2 |

84.0 |

76.0 |

73.1 |

||||||||

Traction current in million kWh |

37.9 |

51.7 |

130.3 |

150.0 |

||||||||

District heating in million kWh |

4.6 |

3.7 |

3.2 |

3.6 |

||||||||

A long-term increase in the percentage of electricity used within the Group’s energy mix will enable the company to utilize more renewable energies and thereby substantially reduce its carbon footprint. HHLA is therefore converting more and more of its equipment and machinery at the terminals to electricity. Such equipment and machinery produces fewer emissions and less noise and is also easier to service. The electricity required by all office buildings and workshops in Hamburg occupied by HHLA, the Container Terminal Altenwerder (CTA) and the all-electric yard crane system at the Container Terminal Burchardkai (CTB) comes from renewables. In the reporting period, these measures reduced CO2 emissions by 23,190 tonnes (previous year: 24,108 tonnes). A photovoltaic system at the Container Terminal Tollerort (CTT) installed and operated by the energy supplier Hamburg Energie Solar produced 111,910 kWh of CO2-free electricity in the year under review.

In addition to the active expansion of renewable energies, HHLA particularly promotes the use of energy-efficient and low-emission machinery and equipment. In the year under review, the fleet of all-electric cars grew by another 13 vehicles to 77. HHLA’s electric vehicles are powered by renewable electricity and are a quiet, low-maintenance solution that does not generate any local emissions. The electric vehicles cover a distance of some 500,000 km each year and thus reduce CO2 emissions by approximately 160 tonnes. In addition, the computer-aided optimisation of container storage positions minimises the distance travelled by transport equipment, thereby reducing energy consumption and noise pollution. The use of retreaded tyres for various container handling machines also helps to improve the company’s use of resources.

Four new straddle carriers that comply with strict requirements of the European Union’s Euro 4 emissions standard went into operation at CTB in the reporting year. With their extremely low emissions, these modern vehicles make an important contribution towards reducing pollution at the container terminal. The world’s first shunting hybrid locomotive for heavy goods trains has been running on the tracks of the Hamburg port railway since summer 2016. The locomotive is used by HHLA subsidiary METRANS. The modern hybrid drive with an electric motor and diesel engine reduces consumption by over 50 %.

Several projects were also continued in the field of energy-efficient lighting. At CTA, the conversion of yard crane lighting to needs-based LED lighting was completed for all 52 yard cranes. As well as reducing lighting emissions, this system cuts electricity consumption by some 90 % compared with the previous, conventional lighting system.

The energy management system that was certified according to DIN ISO 50001 for Hamburger Hafen und Logistik AG and HHLA Personal Service GmbH in the previous year was successfully expanded to additional HHLA companies.

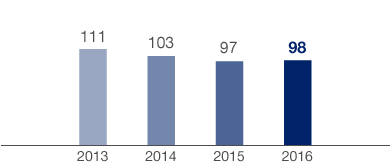

Developments in Water Consumption

in dam3

HHLA locations in Germany, Poland, the Czech Republic, Slovakia and Ukraine.

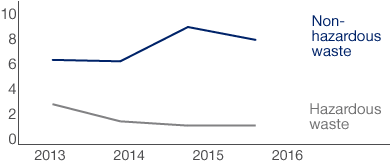

Developments in the Volume of Waste

in thousand tonnes

Water Consumption

Water is mostly used in the HHLA Group to clean large-scale equipment and containers, as well as for employee hygiene. The amount of water consumed by operations in Germany, Poland, Slovakia, the Czech Republic and Ukraine was virtually unchanged year-on-year, rising by 0.5 % to 97,766 m3 in 2016 (previous year: 97,305 m3). HHLA’s facilities in Hamburg draw water from the public supply network.

Waste and Recycling

HHLA reduces refuse and separates rubbish for recycling wherever possible so that reusable waste can be fed back into the resource cycle. Excluding soil and building rubble, the amount of waste produced at the sites in Germany decreased year-on-year by 9.6 % to 8,629 tonnes in the reporting period (previous year: 9,544 tonnes). This is mainly attributable to a 30.5 % decrease in the amount of foodstuffs no longer fit for consumption or further processing, such as bananas, pineapples and potatoes. HHLA has no influence on the amount of such waste, as it includes goods that were already unsuitable when they reached Hamburg. Adjusted for these amounts, the volume of waste at HHLA rose slightly by 1.7 % to 6,307 tonnes in the year under review (previous year: 6,200 tonnes). Hazardous waste declined by 1.6 % to 1,311 tonnes (previous year: 1,322 tonnes). This figure represents a decrease of 60 % compared to 2010. The decrease in hazardous waste is primarily due to the operational start-up of a chemical water treatment plant at CTB. The water used to clean large machinery is treated at the plant before being reintroduced into the cleaning cycle. Overripe bananas and other foodstuffs unsuitable for processing or consumption accounted for the largest proportion of waste in 2016. It declined year-on-year to 2,233 tonnes (previous year: 3,343 tonnes). A large proportion of this was recycled to generate biogas. Approximately 210,000 kWh of electricity was generated without CO2 in this way in 2016, around 90,000 kWh less than in the previous year due to the decrease in these waste volumes. In addition, 0.3 % less commercial waste was generated in the reporting period. At 1,823 tonnes, this type of refuse represented the second-largest waste volume (previous year: 1,828 tonnes). Scrap metal, which was down 3 % on the previous year at 1,105 tonnes (previous year: 1,139 tonnes) was fed completely into the recycling system. There was a significant increase in scrap wood and building timber of 71 % to 691 tonnes, while paper and cardboard packaging rose by 10.9 % to 675 tonnes (previous year: 609 tonnes).

HHLA strives to conserve resources at its terminals, e.g. by using a total of 31,000 tonnes (previous year: 58,300 tonnes) of recycled building materials to maintain its terminal areas during 2016. Of this amount, slag from waste incineration and asphalt recycling accounted for the largest shares (11,000 tonnes each). 7,000 tonnes of electric furnace slag, which results from the melting of steel scrap and mineral additives in electric arc furnaces, was also recycled and will now be reused as aggregate at the terminals. The use of this recycled building material means that less natural stone needs to be mined. A further 2,000 tonnes of recycled concrete-mineral aggregates were used for site redevelopment.

The action of a locomotive pulling a train.

In maritime logistics, a terminal is a facility where freight transported by various modes of transport is handled.

In maritime logistics, a terminal is a facility where freight transported by various modes of transport is handled.

A vehicle used to transport containers at the terminals. The driver manoeuvres their straddle carrier into position above a container and lifts it up. The vehicles can stack containers up to four high.