Waste and Recycling

Developments in the Volume of Waste

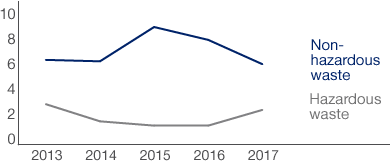

in thousand tonnes

HHLA aims to reduce – and also separates waste for recycling wherever possible so that reusable waste can be fed back into the resource cycle. The amount and composition of waste can vary significantly over time. Excluding soil and building rubble, the amount of waste produced at the sites in Germany decreased year-on-year by 7.0 % to 8,023 tonnes in the reporting period (previous year: 8,629 tonnes). Within the overall waste total, hazardous waste increased to 2,398 tonnes (previous year: 1,311 tonnes). This rising volume was primarily attributable to a larger quantity of sludge from oil/water separators. Despite a 16.9 % decrease, commercial waste for recovery and mixed packaging accounted for 18.8 % or 1,515 tonnes – and thus the largest waste volume – in the reporting period. Sludge from oil/water separators, which is mainly produced when large machines are cleaned, was the second-biggest type of waste with a share of 17.1 %. Compared with the previous year, this type of waste grew by 126 %, taking it to 1,372 tonnes. In addition to the increased need to clean large machines as a result of throughput growth, this stemmed from necessary modification work to a water treatment plant. The quantity of fruit and other food waste such as bananas, pineapples and potatoes fell by 48.7 %, or 1,131 tonnes, to 1,191 tonnes in the reporting year. HHLA has no influence on the amount of such waste, as it usually includes goods already unfit for consumption upon arrival in Hamburg. A large proportion was recycled to generate biogas. Approximately 180,000 kWh of electricity was generated without CO2 in this way in 2017. The amount of scrap metal fed completely into the recycling system increased by 5.8 % to 1,169 tonnes in the reporting period. Paper and cardboard packaging was down 15.1 % at 573 tonnes, and there was a significant reduction of 49.3 % in scrap wood and building timber.

HHLA strives to conserve resources at its terminals, e.g. by using a total of 18,881 tonnes (previous year: 31,000 tonnes) of recycled building materials to maintain its terminal areas during 2017. At 10,293 tonnes, the majority of this was asphalt recycling. 3,814 tonnes of electric furnace slag was used during the renovation of a container rail terminal at the Container Terminal Burchardkai. Electric furnace slag is produced when steel scrap and mineral additives are melted in electric arc furnaces. It is reused as aggregate at the terminal sites. 3,177 tonnes of slag from waste incineration bonded with cement was also used during the renovation of the rail terminal. In addition to this, 1,597 tonnes of recycled concrete-mineral aggregates were reused for site redevelopment.

In maritime logistics, a terminal is a facility where freight transported by various modes of transport is handled.

In maritime logistics, a terminal is a facility where freight transported by various modes of transport is handled.